About us

We devote ourselves into '

creating

new technology'

and contribute to

bright evoluation of mankind.

We, CONNECTEC JAPAN love our country and world peace, and wish to contribute to future of world manufacturing through development of semiconductor and electronics components and production technology. We believe that 'feeling joy for work' is fundamental virtue of human being and 'day-to-day work' is our real joy for life. CONNECTEC JAPAN firmly committed to continue to create 'joys for work' and share the joy with many friends in the world. CONNECTEC JAPAN shall keep improving day by day and 'creating new technology' for bright future of mankind.

SERVICE

User Centric Design

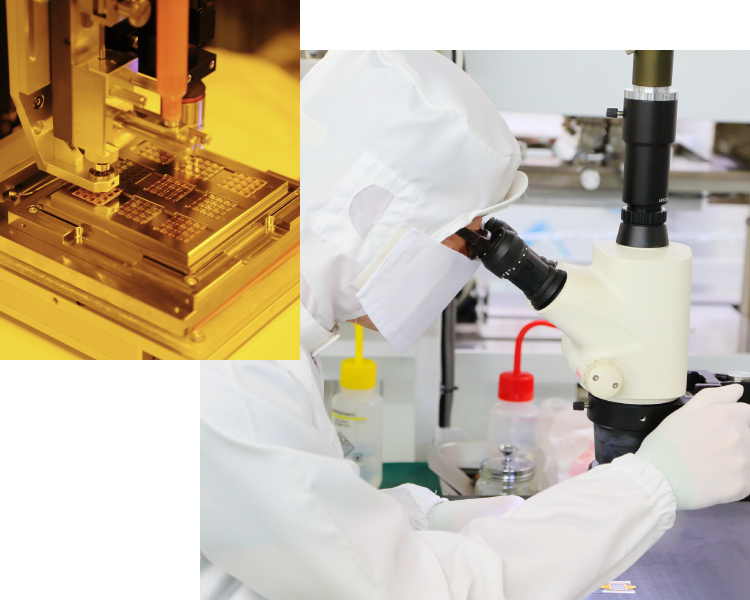

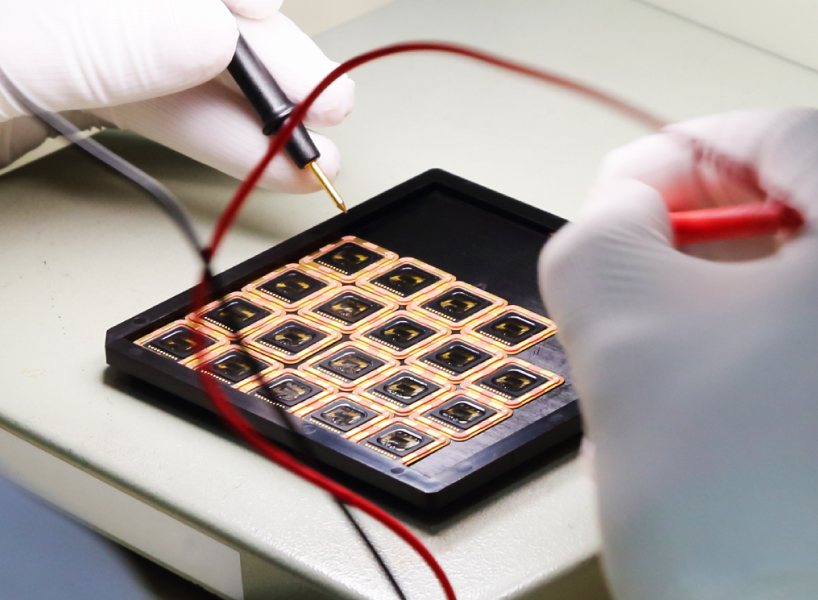

We will totally support your requests from assembling semiconductor chips, MEMS chips, surface mounting, module proto-typing, evaluation/analysis, reliability test, mass-production. We will also respond to request from clients in cooperation with our partner companies.

OSRDA

According to the requirement from the clients,we will provide our proposal on concrete structure,design,proto-typing,and mass-production.

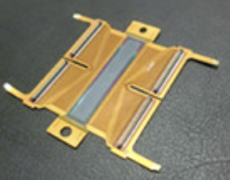

CASE

Low load damage-free assembly.

We are confident to be sure to meet your expectation.

Company

News

There are no articles currently.

CONNECTEC Japan is

currently recruiting personnel

due to business operation expansion.